Innovation

A Change to Better The Future of Playgrounds

Innovation has been at the heart of who we are from day one. As our company’s grown, our process has become more sophisticated and collaborative. From design to manufacturing, safety to sustainability, efficiency to accessibility, our employees have thought so far outside the box, that one moment we’re being told, “it will never work,” and the next, we’re being followed.

Continuous Play

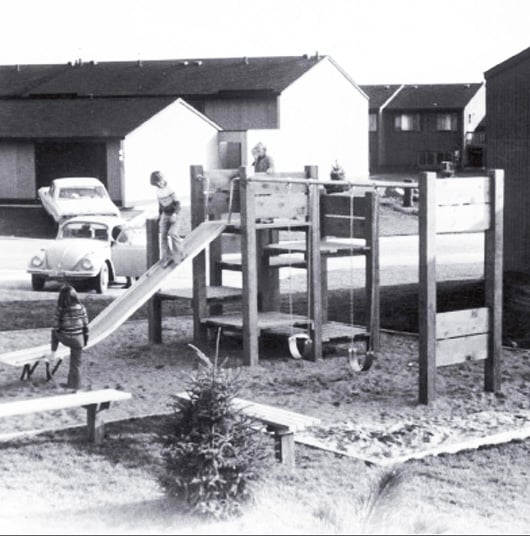

In the mid-1960s, playgrounds meant freestanding metal equipment with a large footprint, resulting in a less natural and challenging play experience for many children. A young landscape architecture student named Steve King had a crazy idea. What if play components were attached so kids could move from play event to play event without ever touching the ground, creating a “continuous play” experience?

In the mid-1960s, playgrounds meant freestanding metal equipment with a large footprint, resulting in a less natural and challenging play experience for many children. A young landscape architecture student named Steve King had a crazy idea. What if play components were attached so kids could move from play event to play event without ever touching the ground, creating a “continuous play” experience?

Continuous Play brought more play value to a smaller space, more social interactions and more skill development among children. The idea led to the formation of Landscape Structures and marked a first of many revolutions for the playground equipment industry.

For decades, we’ve paid attention not only to how children play together, but who can play together. The playground is a place where kids of all abilities should be able to interact and play side by side. Learn more.

Inclusive and Accessible Play

In order to create a truly inclusive playground, it not only needs to be accessible, but also age and developmentally appropriate and stimulating to the senses. We work collaboratively with an Inclusive Play Partners to ensure our Higher Level of Inclusive Play™ helps kids develop, build confidence, make friends and play as equals. Learn more.

In order to create a truly inclusive playground, it not only needs to be accessible, but also age and developmentally appropriate and stimulating to the senses. We work collaboratively with an Inclusive Play Partners to ensure our Higher Level of Inclusive Play™ helps kids develop, build confidence, make friends and play as equals. Learn more.

Innovative Playground Design

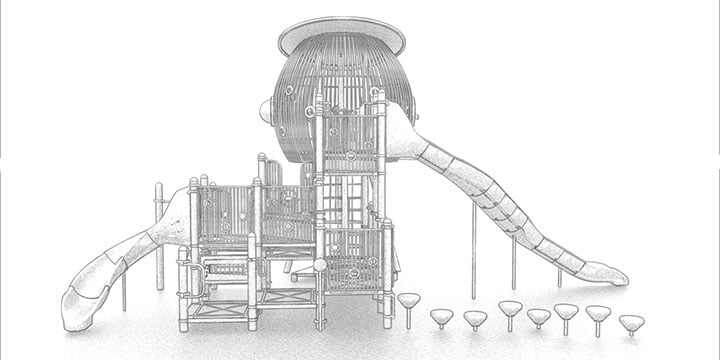

As we continue to grow, more and more people have a voice in our design decisions. In addition to our designers, teams from different disciplines collaborate on the product development process: engineering, testing, manufacturing, marketing, sales and packaging. A good idea can come from anywhere, and many of our innovations soon become industry standards.

As we continue to grow, more and more people have a voice in our design decisions. In addition to our designers, teams from different disciplines collaborate on the product development process: engineering, testing, manufacturing, marketing, sales and packaging. A good idea can come from anywhere, and many of our innovations soon become industry standards.

Precision Manufacturing

We utilize precision manufacturing techniques that ensure consistency, safety and durability in every playground product we make. From personalized 3D CAD design to robotic welding to extensive product testing, we leave nothing to chance.

We utilize precision manufacturing techniques that ensure consistency, safety and durability in every playground product we make. From personalized 3D CAD design to robotic welding to extensive product testing, we leave nothing to chance.

Our goal is that every piece of our playground equipment, every finish and every coating is built to last through this generation of children, and on to the next. And our equipment is created to be as safe on the ten-thousandth use as it is on the first.

Things like tighter manufacturing tolerances, better fasteners, smaller gaps and no-flake finishes mean no pinched fingers, caught clothing or other safety hazards. And that’s good for everyone.

Because of our precision manufacturing and use of only the best materials, our products are built to last.

Sustainable Practices by Employee Owners

Sustainability has always been an important part of our culture, even before there was a word for it. In 1998, we became the first playground equipment manufacturer in North America to be ISO 14001 certified for environmental stewardship.

Each of our employee-owners is committed to producing the highest-quality, most environmentally preferable products available for longer-lasting, sustainable products that are built to last for years—and generations—to come. You have our word. Learn more.

Industry Leading Innovations and Materials

Sway Fun® Glider

We premiere 10 to 20 new products every year. We’re especially proud of our innovations in designing inclusive play environments. The Sway Fun® Glider, introduced in 2002, is a first-multi-user glider that was the first of its kind to be accessible to children and adults in wheelchairs, meeting all safety standards, while allowing users to control the motion. This is often the first time children in mobility devices experience a swinging motion and provides parents in mobility devices the ability to play with their children.

We premiere 10 to 20 new products every year. We’re especially proud of our innovations in designing inclusive play environments. The Sway Fun® Glider, introduced in 2002, is a first-multi-user glider that was the first of its kind to be accessible to children and adults in wheelchairs, meeting all safety standards, while allowing users to control the motion. This is often the first time children in mobility devices experience a swinging motion and provides parents in mobility devices the ability to play with their children.

TenderTuff™

Around 1981, we began coating decks and steel parts—anything that kids touched and could cut themselves on or burn themselves on during hot, sunny days—with TenderTuff coating, otherwise known as PVC (polyvinyl chloride).

Steve King became interested in PVC when he was fiddling with his freezer and he noticed that his hand didn’t stick to the shelving. Everyone said it wouldn’t work. Three years later, everyone was using this material. TenderTuff changed the industry again and, like continuous play, is now an industry standard.

Permalene®

At first, Steve designed all of the innovations. He’d walk through a shopping center and see some detail on a guardrail or furnishing, and pretty soon incorporate that detail into our equipment.

Looking at the partitions in an airport bathroom, Steve realized that the same compressed polyethylene material could work as activity panels in our playground equipment. From that notion, we introduced Permalene® in 1985. These kid-friendly panels and components continue to look new, year after year. In 2010, a 73% post-consumer recycled option was added for our enclosures.

Glass-Fiber Reinforced Concrete

Glass Fiber Reinforced Concrete, or GFRC, is tough-as-nails, has a rugged, rock-like texture that never feels artificial. In fact, molds are created from real trees and rock formations for the most realistic look and feel. And it hardens over time to deliver years of reliable fun in any environment.Beyond rocks and logs, GFRC offers the flexibility to provide almost any unique element to any playground, from dolphins to lollipops to spaceships to dinosaur bones.

Glass Fiber Reinforced Concrete, or GFRC, is tough-as-nails, has a rugged, rock-like texture that never feels artificial. In fact, molds are created from real trees and rock formations for the most realistic look and feel. And it hardens over time to deliver years of reliable fun in any environment.Beyond rocks and logs, GFRC offers the flexibility to provide almost any unique element to any playground, from dolphins to lollipops to spaceships to dinosaur bones.

We’re the only playground manufacturer in the industry with an in-house concrete plant. Opened in 2011, our world-class, sustainable manufacturing facility offers inhouse design, engineering, manufacturing and installation—both for traditional play systems and concrete components. And being all vertically integrated within one facility enables us to bring any playground theme or idea to life.